Mechanical clamping sets – The force-fit connection for the most demanding requirements

Mechanical clamping sets are high-precision machine elements used for the backlash-free connection of shafts and hubs. They enable reliable torque transmission without keyways or splined shafts, ideal for modern drive solutions.

Catalogue - mechanical clamping elements

Operating principle

Clamping sets consist of conical inner and outer rings that are moved against each other by tightening screws. This movement generates radial pressure, which creates a friction-locked connection between the shaft and hub – completely without play.

Advantages at a glance

- Cost-efficient - especially for one-time or infrequent assembly operations

- Ideal for fixed, permanent connections

- Absorption of high radial forces

- Suitable for high temperature ranges

- Can also be used with grooved shafts

Typical areas of application

- Drive technology (e.g., motors, gearboxes)

- Conveyor systems

- Packaging and production machines

- Machine tools

You can find the relevant CAD data on our SELENA Engineering Platform. We are happy to assist you with any customer-specific requirements. Simply contact our technicians at engineering@lenze-selection.com.

Mechanical clamping sets – self-centering

SEL1100

- Medium to high transmissible torques (11 – 25.257 Nm)

- Available for shaft diameters of 6 to 130 mm

- Self-centering

- Low surface pressure

- Suitable for hubs with low yield strength

- No axial displacement when tightening the screws

- Compact dimensions

SEL4000

- High transmissible torques (3.490 – 864.290 Nm)

- Available on request for shaft diameters of 45 to 600 mm

- Self-Centering

- No axial displacement during assembly

- Good concentricity and perpendicularity

SEL4500 / SEL4520

- Very high transmissible torques (849 – 931.746 Nm)

- Available for shaft diameters of 25 to 400 mm

- Self-centering

- Even pressure distribution

- No axial displacement when tightening screws

- Removal via extraction threads

- Excellent perpendicularity

SEL1300

- High transmissible torques (492 – 95.058 Nm)

- Available for shaft diameters of 18 to 200 mm

- Self-centering

- Even pressure distribution

- Axial displacement when tightening screws

- Excellent shaft-to-hub perpendicularity

- Quick installation and removal

SEL1310

- Medium to high transmissible torques (307 – 51.399 Nm)

- Available for shaft diameters of 18 to 200 mm

- Self-centering

- Low surface pressure

- Quick installation and removal

- No axial displacement when tightening the screws

- Excellent shaft-to-hub perpendicularity

SEL1320

- Hight transmissible torques (331 – 64.796 Nm)

- Available for shaft diameters of 18 to 200 mm

- Self-centering

- Axial displacement when tightening screws

- Optimal shaft-to-hub perpendicularity

- Quick installation and removal

- Reduced axial dimensions

SEL1330

- Medium to high transmissible torques (252 – 49.305 Nm)

- Available for shaft diameters of 14 to 50 mm

- Self-centering

- No axial displacement when tightening the screws

- Excellent concentricity and perpendicularity

SEL1340

- Medium to high transmissible torques (221 – 1.838 Nm)

- Available for shaft diameters of 14 to 50 mm

- Self-centering

- Low surface pressures

- Quick installation and removal

- No axial displacement when tightening the screws

- Excellent concentricity and perpendicularity

SEL1390

- Medium to high transmissible torques (8 – 2.260 Nm)

- Available for shaft diameters of 5 to 50 mm

- Self-centering

- Quick installation and removal

- Slight axial displacement when tightening screws

- Excellent shaft-to-hub concentricity and perpendicularity

- During assembly, it generates an axial force that can be used to axially clamp bearings or other components adjacent to the hub

SEL160

- Medium to high transmissible torques (108 – 2.143 Nm)

- Available for shaft diameters of 14 to 65 mm

- Self-centering

- Effective alternative to SEL3000: no flange or spacer required

- Quick installation and removal

- Tolerance h8 for shaft, H8 for hub

- Axial displacement during assembly

- Bolts NOT included as their length, being related to end-use, can’t be set in advance

SEL180

- High transmissible torque (280 – 4.607 Nm)

- Available for shaft diameters of 20 to 70 mm

- Self-centering

- Axial displacement when tightening screws

- Optimal shaft-to-hub perpendicularity

- Reduced axial dimensions

- Quick installation and removal

SEL2500 L

- Medium to high transmissible torques (66 – 1.398 Nm)

- Available for shaft diameters of 14 to 70 mm

- Self-centering

- Axial displacement when tightening the locking nut

- Good perpendicularity

Mechanical clamping sets – not self-centering

SEL2000

- Very high transmissible torques (315 – 1.278.800 Nm)

- Available for shaft diameters of 17 to 600 mm

- Easy removal

- Possible use on shaft-hubs with large tolerances (h11/H11)

SEL2500

- Medium to high transmissible torques (45 – 1.475 Nm)

- Available for shaft diameters of 14 to 70 mm

- Not self-centering

- Easy installation and removal

- Axial displacement when tightening the locking nut

SEL3000

- Medium to low transmissible torques (3 – 51.000 Nm)

- Available for shaft diameters of 6 to 240 mm

- Not self-centering

- No axial displacement during assembly

- Requires threads in the hub

- Requires a thrust flange

- Quick installation and removal

- No axial displacement during assembly

SEL5000

- Medium to high transmissible torques (173 – 5.411 Nm)

- Available for shaft diameters of 17 to 80 mm

- Perfect axial alignment

- No backlash

- Quick installation

- Tolerance h8 for shaft, H8 for hub

Customized versions available on request (not self-centering)

SEL4510

- Medium to high transmissible torques (values without bending moment: 7.300 – 866.000 Nm; values with maximum bending moment: 5.271 – 747.654 Nm)

- Available on request for shaft diameters of 70 to 600 mm

- For applications with high bending moments

- Quick installation and removal

- No axial displacement when tightening the screws

- Excellent concentricity and perpendicularity

SEL3500 special

- Medium to high transmissible torques (8 – 2.260 Nm)

- Available on request for shaft diameters of 5 to 50 mm

- Excellent concentricity and perpendicularity

- No axial displacement during assembly

- Low surface pressures

- Reduced axial dimensions

- Easy to remove

Shrink discs

SEL6010, SEL6020, SEL6030, SEL6030 12.9

- High torques

- Available for shaft diameters of 14 to 1000 mm

- Easy installation & removal

- Four available versions:

SEL6030 (Mt: 32 - 1.310.000 Nm), standard series (recommended)

SEL6030 12.9 (Mt: 245 – 1.580.000 Nm), SEL6030 with 12.9 screws

SEL6020 (Mt: 15.000 – 1.500.000 Nm), heavy duty series

SEL6010 (Mt: 10.550 – 935.000 Nm), lightweight series

SEL6210, SEL6220, SEL6230, SEL6810, SEL6830

- Very high torques

- Available for shaft diameters of 12 to 1000 mm

- Quick installation and removal

- Five available versions:

SEL6220 (Mt: 20 – 3.912.000 Nm), standard series (recommended)

SEL6810 (Mt: 1.500 – 4.727.000 Nm), SIT-Lock 1422 with 12.9 screws

SEL6230 (Mt: 26.000 – 3.272.000 Nm), heavy duty series

SEL6830 (Mt: 30.000 – 3.956.000 Nm), SIT-Lock 1423 with 12.9 screws

SEL6210 (Mt: 16.000 – 4.033.000 Nm), lightweight series

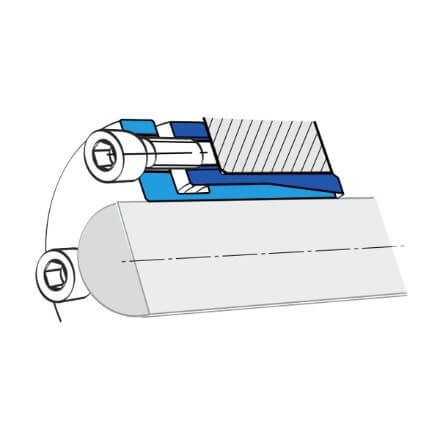

Single screw clamping element

SEL300 & SEL400

The SEL300/SEL400 consists of a single cylindrical ring with a tapered hole cut into it. A special screw with a tapered surface is inserted into the tapered hole. Tightening the screw exerts pressure on the shaft and hub. This pressure enables the transmission of torque.

Features:

- Quick and easy assembly and disassembly

- No axial displacement between hub and shaft when tightening the screws

- Economical

- Compact dimensions